FUME CUPBOARD TESTING

HEPA FILTER TESTING

/

FUME CUPBOARD TESTING

/

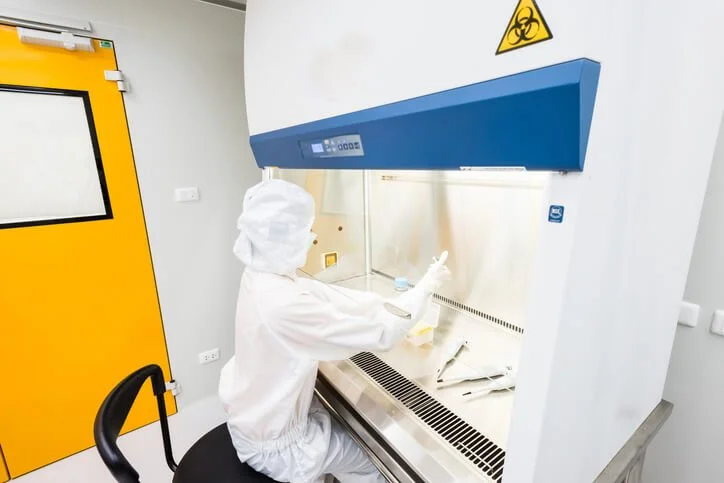

BIOLOGICAL SAFETY CABINETS

/

CLEAN WORK STATIONS

/

CYTOTOXIC DRUG SAFETY CABINET TESTING

/

CLEANROOM VALIDATION

/

HEPA FILTER TESTING / FUME CUPBOARD TESTING / BIOLOGICAL SAFETY CABINETS / CLEAN WORK STATIONS / CYTOTOXIC DRUG SAFETY CABINET TESTING / CLEANROOM VALIDATION /

Fume cupboards serve as your laboratory’s first line of defence against hazardous exposure. These systems protect personnel from dangerous chemicals, vapours, and fumes - but only when every component is performing as it should.

Why Does Testing

Matter?

The safety and efficiency of fume cupboards and cabinets depend on mulitple systems working in harmony. If airflow, extraction, or sealing is compromised, personnel can be exposed to serious health risks.

Testing Schedule

Requirements.

Commissioning

All new fume cupboards and cabinets must be tested by a NATA-accredited laboratory before being placed in service.

Ongoing Maintenance

6-monthly inspections: Recommended for ongoing performance monitoring.

Annual certification: Full testing required to maintain compliance.

Key performance factors

requiring regular verification

Don’t wait until your systems fail.

Schedule your HEPA filter testing today.

Our role is to support the safe, reliable operation of your controlled environments.

Contact us today.

Comprehensive Test Suite

/01

SMOKE TESTING

Verifies proper airflow patterns and containment.

/02

FACE VELOCITY MEASUREMENT

Ensures adequate capture velocity.

/03

NOISE LEVEL ASSESSMENT

Confirms a comfortable working environment.

/04

CUSTOMER FIRST PHILOSOPHY

Validates adequate workspace lighting.

COMPLIANCE AND STANDARDS

Our testing protocols ensure full compliance with:

Fume Cupboards: AS/NZS 2243.8 (2014)

Fume Cabinets: AS/NZS 2243.9 (2009)

These standards ensure both safety and performance, reducing operational hazards.

With AG&G Services, you can be confident that every element of your fume cupboards and cabinets is functioning as designed.

Our NATA-accredited testing delivers peace of mind that your laboratory remains safe, compliant, and fully operational.