HEPA FILTER TESTING

HEPA FILTER TESTING

/

FUME CUPBOARD TESTING

/

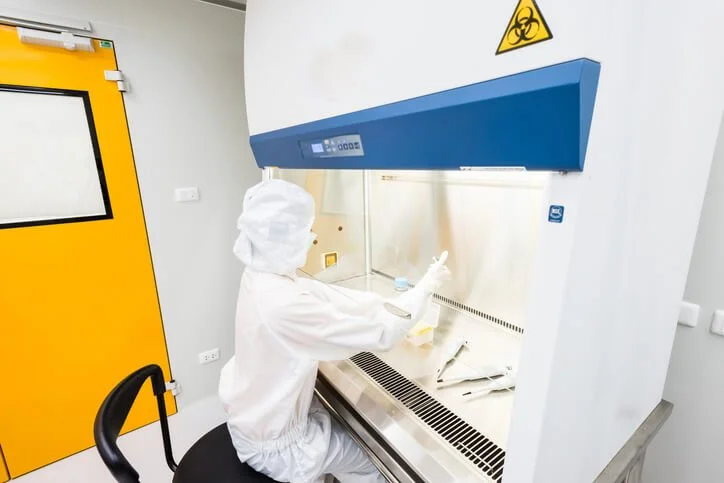

BIOLOGICAL SAFETY CABINETS

/

CLEAN WORK STATIONS

/

CYTOTOXIC DRUG SAFETY CABINETS TESTING

/

CLEANROOM VALIDATION

/

HEPA FILTER TESTING / FUME CUPBOARD TESTING / BIOLOGICAL SAFETY CABINETS / CLEAN WORK STATIONS / CYTOTOXIC DRUG SAFETY CABINETS TESTING / CLEANROOM VALIDATION /

HEPA filter testing is essential for maintaining the integrity of your controlled environment. Even the highest-quality filters can develop leaks through manufacturing defects, incorrect installation, or natural wear over time. As filters accumulate contaminants, their efficiency can be compromised, putting your entire operation at risk.

The Consequences

of Undetected Filter Failure Include:

• Contamination of critical processes

• Product quality issues

• Regulatory non-compliance

• Expensive production shutdowns

Accredited testing

you can trust.

Routine integrity testing and pressure drop monitoring reduce these risks, keeping systems reliable and operations running smoothly.

AG&G Services is NATA-accredited to perform comprehensive HEPA filter testing using both DPC and DOP methods, ensuring full compliance with:

• AS/ISO 14644.3 (2021)

• AS 1807.6–7 (2000)

Our reports provide clear, audit-ready evidence that your filtration systems are performing as designed.

-

On-site commissioning: Before any equipment enters service

After filter replacement: Verifying new filters perform to specification

Following relocation: Confirming integrity after workstations or cabinets are moved

-

After electrical maintenance: Ensuring system integrity remains intact

After mechanical maintenance: Verifying no damage occurred during service

-

Annual verification: Minimum requirement for ongoing performance assurance

Regulatory compliance: As mandated by GMP codes or governing authorities

-

Operational changes: When processes are significantly modified

Performance concerns: If reduced operation is suspected or detected

Post-incident verification: Following any event that may affect filter integrity

AG&G Services can help you develop a tailored testing schedule aligned to your operational needs and regulatory requirements.

What makes us different

/01

FORENSIC DOCUMENTATION

Every test report is audit-ready, with calibrated equipment, references and detailed analysis.

/02

STRATEGIC INSIGHTS

We identify optimisation opportunities and recommend preventative measures before issues arise.

/03

QUALITY GUARANTEE

Replacement parts always meet or exceed original specifications.

/04

CUSTOM PROTECTION PLANS

Maintenance programs tailored to your operations and risk profile.

/05

TRIPLE-CERTIFIED EXCELLENCE

Three NATA signatories ensure consistent, reliable service delivery.

/06

CUSTOMER-FIRST PHILOSOPHY

Responsive service and a focus on ensuring your needs meet evolving contamination control standards.

While others offer testing services, we deliver compliance assurance.

Your controlled environments are too critical to trust to anyone else.