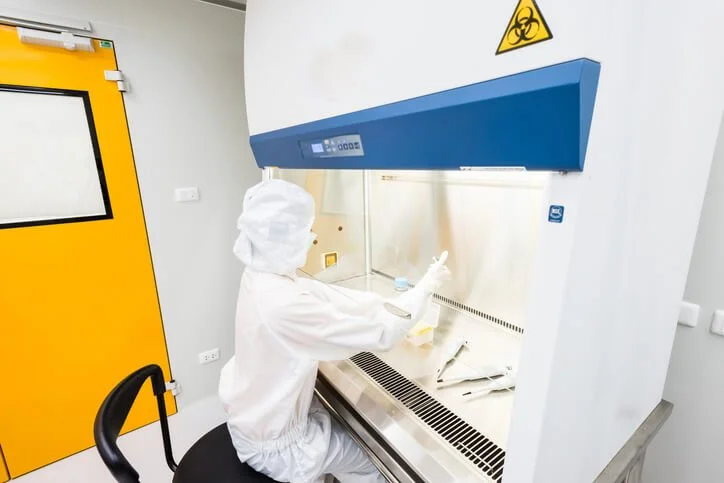

CLEAN WORK STATIONS

HEPA FILTER TESTING

/

BIOLOGICAL SAFETY CABINETS

/

FUME CUPBOARD TESTING

/

CLEAN WORK STATIONS

/

CYTOTOXIC DRUG SAFETY CABINET TESTING

/

CLEANROOM VALIDATION

/

HEPA FILTER TESTING / BIOLOGICAL SAFETY CABINETS / FUME CUPBOARD TESTING / CLEAN WORK STATIONS / CYTOTOXIC DRUG SAFETY CABINET TESTING / CLEANROOM VALIDATION /

Laminar flow cabinets, or clean work stations, create ultra-clean, particle-free environments essential for protecting sensitive products and processes. They rely on advanced HEPA filtration and unidirectional airflow to maintain contamination-free conditions.

How do they work?

Air passes through pre-filters and HEPA filters (removing particles down to 0.3 microns), then flows in a smooth, laminar stream across the work surface. This continuous airflow maintains a controlled environment that protects products from airborne contamination.

Product Protection Only

Important: These cabinets protect products, not personnel. Never use with viable pathogens or hazardous biological materials.

Industry Applications

Clean work stations are critical for contamination-sensitive tasks, including:

-

Sterile compounding and drug preparation.

-

Cell culture and sample preparation.

-

Precision assembly and testing.

Ensure optimal performance with professional testing from AG&G Services.

Main tests provided for clean work stations

AG&G Services provides professional testing to ensure your clean work stations operate as designed.

With regular validation, you can maintain product saftey, meet compliance standards, and protect the integrity of your processes.